Tadpole Pigs

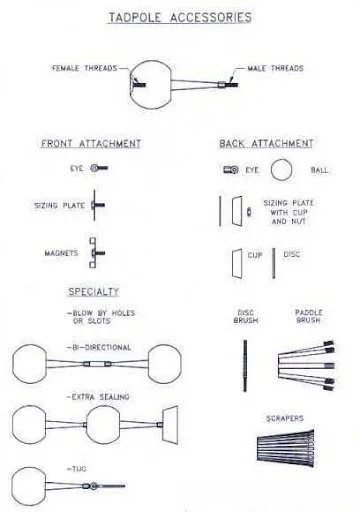

BKW’s patented Tadpole Pig is a cleaning pig used for testing and dewatering gathering systems and was designed for running through short radius weld ells and tees. Attachments can be added such as cups, brushes, and scrapers.

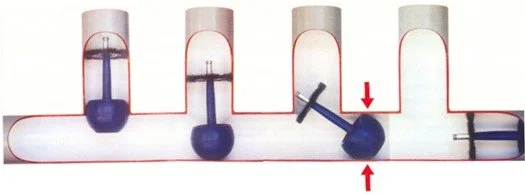

Pictures below shows the Tadpoles ability to pass through tees with a minimum of blow by. Arrows indicate where the Tadpole seals against pipe wall.

Pictures below shows the Tadpole’s sealing ability in a 90-degree ell using the trailer ball and steel brushes. Arrows indicate location of sealing against pipe wall.

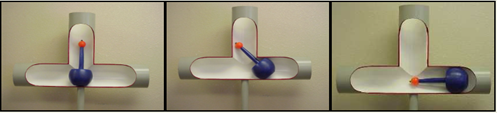

The Tadpole Pig progressing through a typical ell.

BKW Tadpole Pig Features

The Tadpole Pig is made to go through fittings with a minimum of pressure drop. All pigs, including foam pigs, must bend when going through fittings. The Tadpole does not have to bend; therefore, the Tadpole does not have to slow down waiting for pressure buildup. This unique feature has advantages when filling or dewatering a line during hydrostatic testing and is especially true for pipelines not designed for pigging.

The Tadpole Pig has a male thread on the tail for attaching anything that is required to perform a function inside a pipeline. This can be brushes, scrapers, cups, or magnets. It can even be used to pull smart pigs or cables. The male thread is connected to a female thread in the nose of the pig using a cable. The female thread can be used to attach a sizing plate, magnets, cable eyes or another Tadpole Pig.

The Tadpole Pig can be furnished with bypass holes for cleaning new pipelines or scraping wax and other films from pipe walls. This process will prevent buildup and possible plugging of the pipeline.

The Tadpole Pig is flexible and can penetrate pipe with large dents and buckles or travel through reduced opening valves.

The Tadpole Pig is easily adapted for multiple automatic pig launchers in remote pig launching operations, including deep water pipelines.